We are pleased to announce the release of TwinMesh™ 2022. This brand new release of TwinMesh™ includes many new features that further improve the quality of meshes for complex geometries. For example the new node on geometry mapping feature allow even more accurate investigations of the flow in the radial gaps of your machine. We also added the possibility of changing the element orientation in order to better follow the wrapped shape of complex twisted geometries. Read further for getting information about new features in TwinMesh™ 2022:

TwinMesh creates meshes with different approaches to handle the complex geometries of each type of engine. The new version of TwinMesh adds some export options to the “OuterFix” meshing method. It changes the element orientation to follow the rotor wrap and to keep good mesh quality. The number of nodes keeps the same. The available options are:

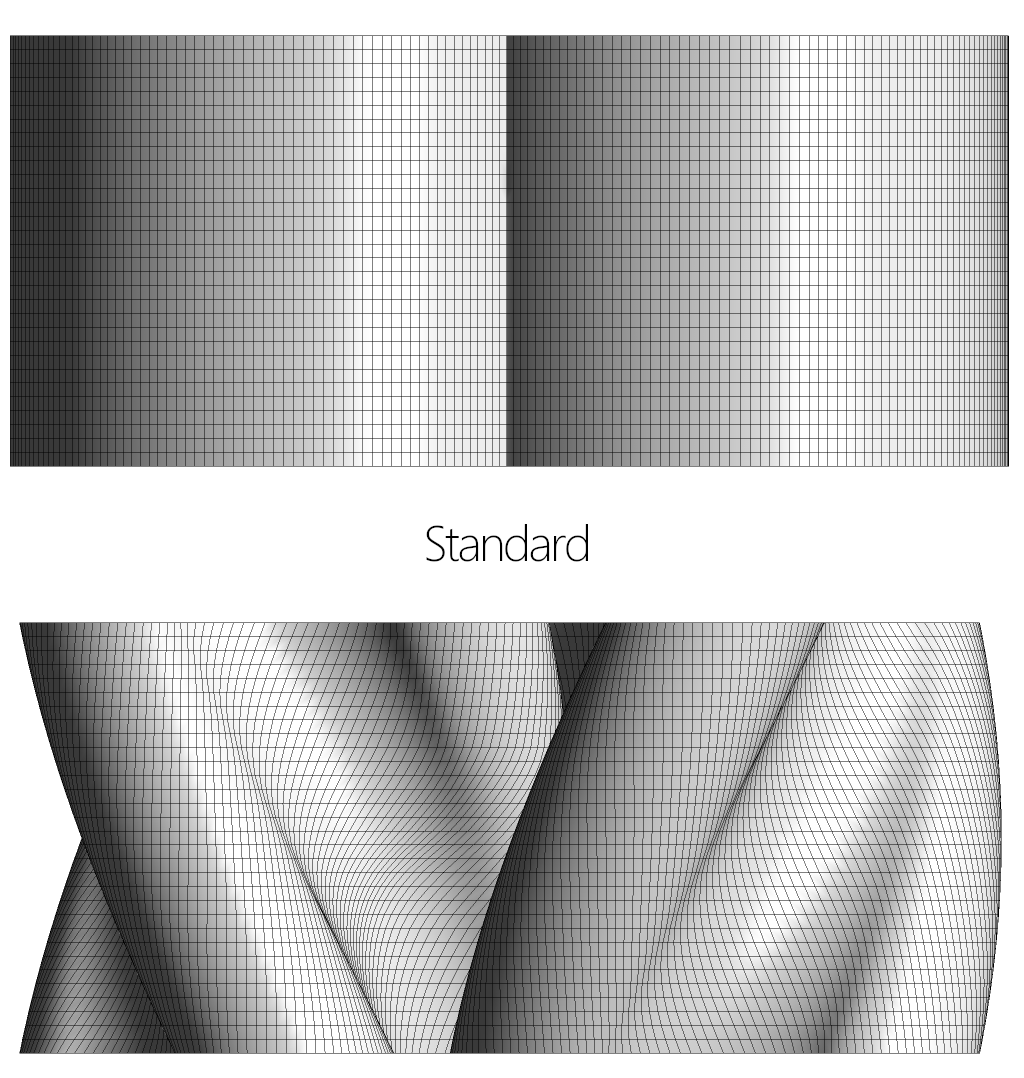

Standard

The standard option connects the 2D meshes of each mesh section to a 3D mesh only with hexahedrons. The following new options are based on the topology of this mesh.

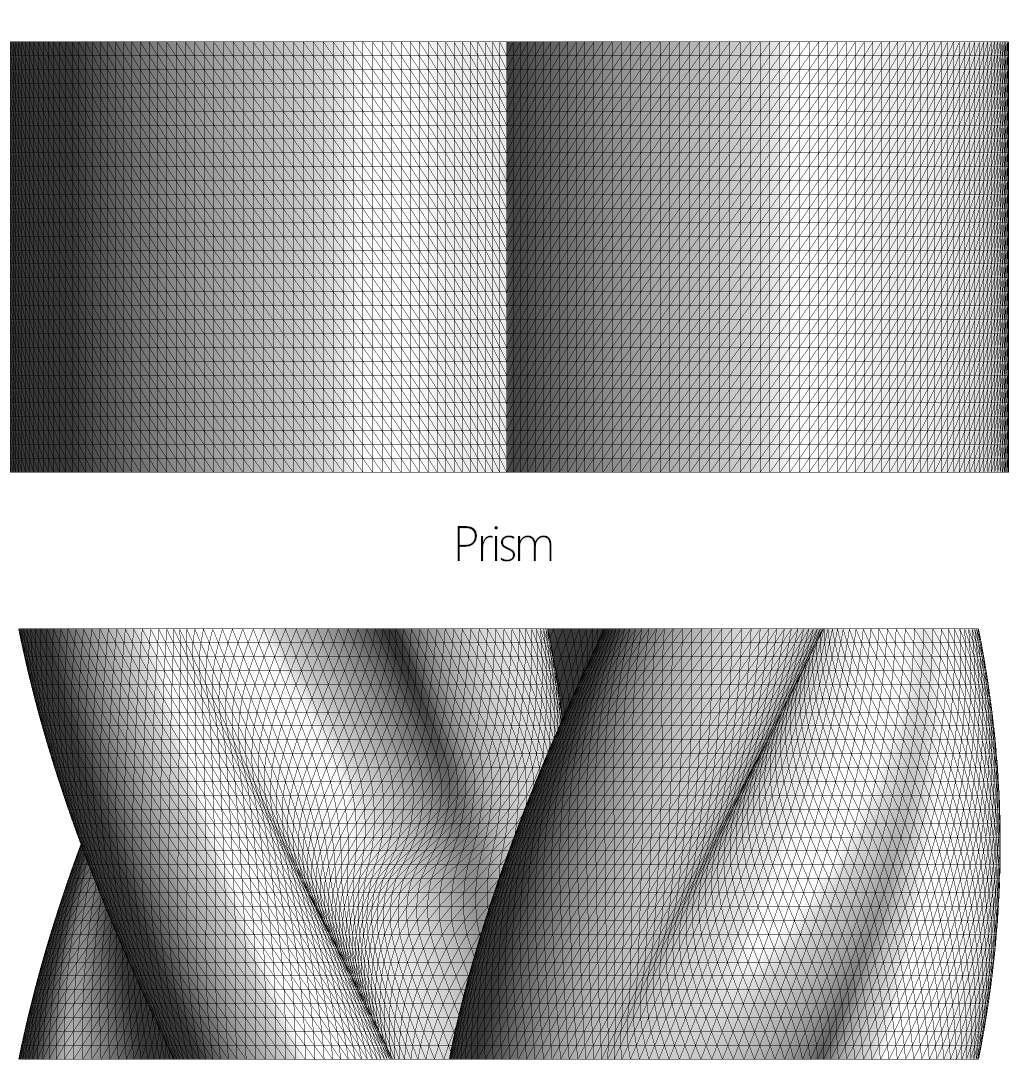

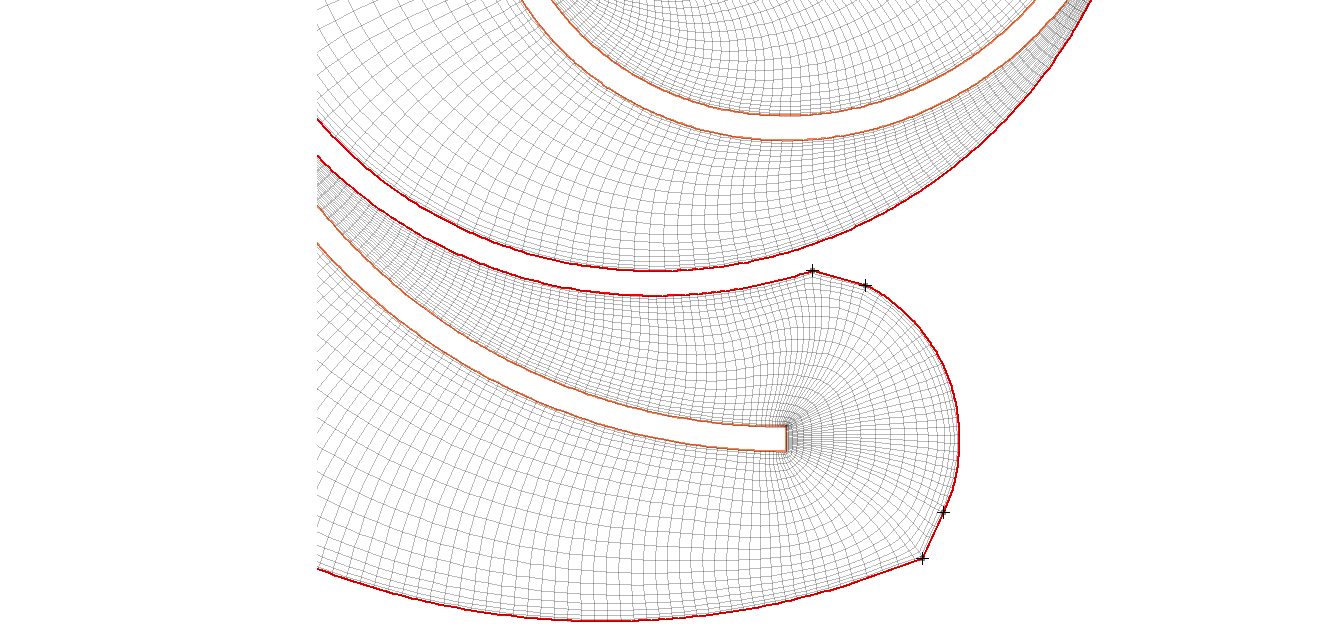

Prism (new)

This new option in TwinMesh™ 2022 cuts each hexahedral element into two prisms, where the cut face follows the wrap rotation. It enhances the “OuterFix” method and orientates the element faces along the radial gaps to discretize the gap size more accurate.

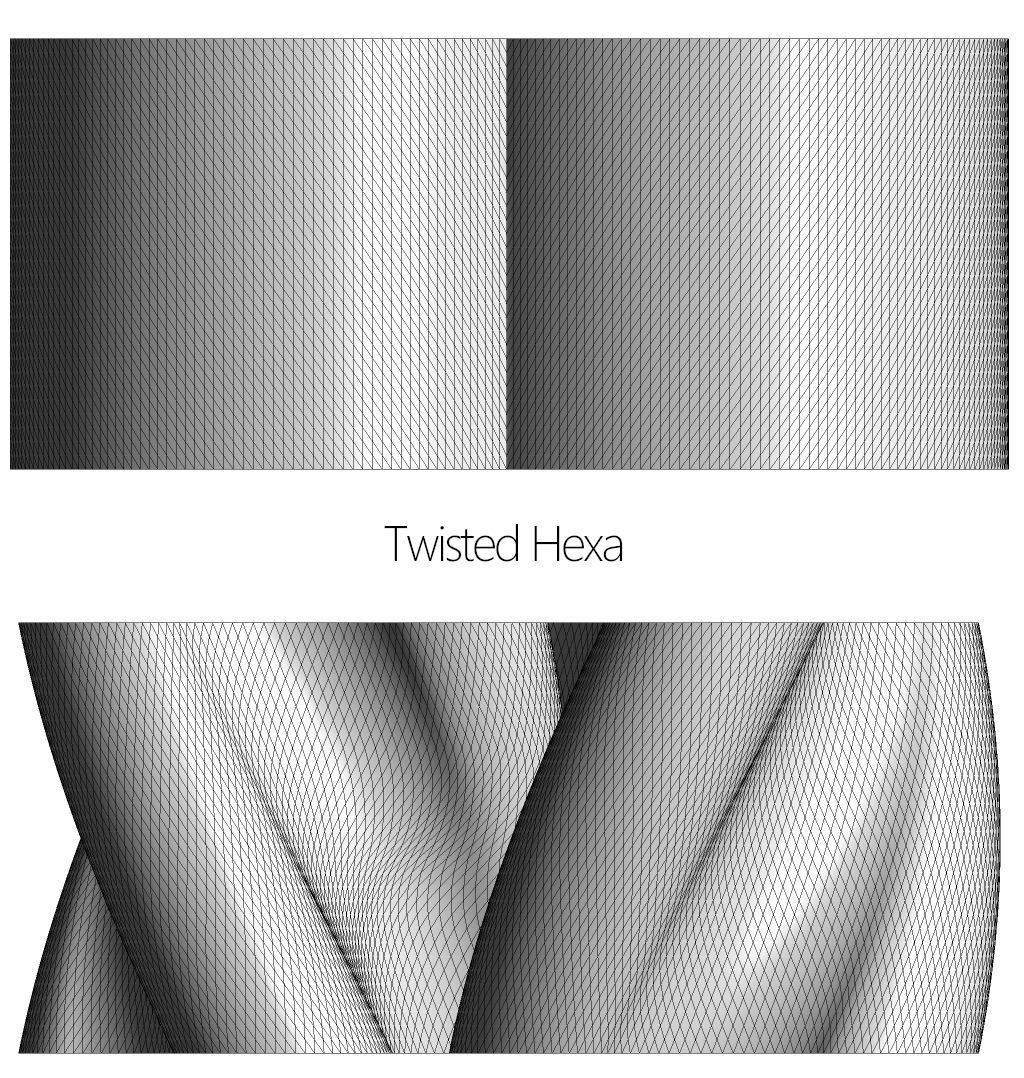

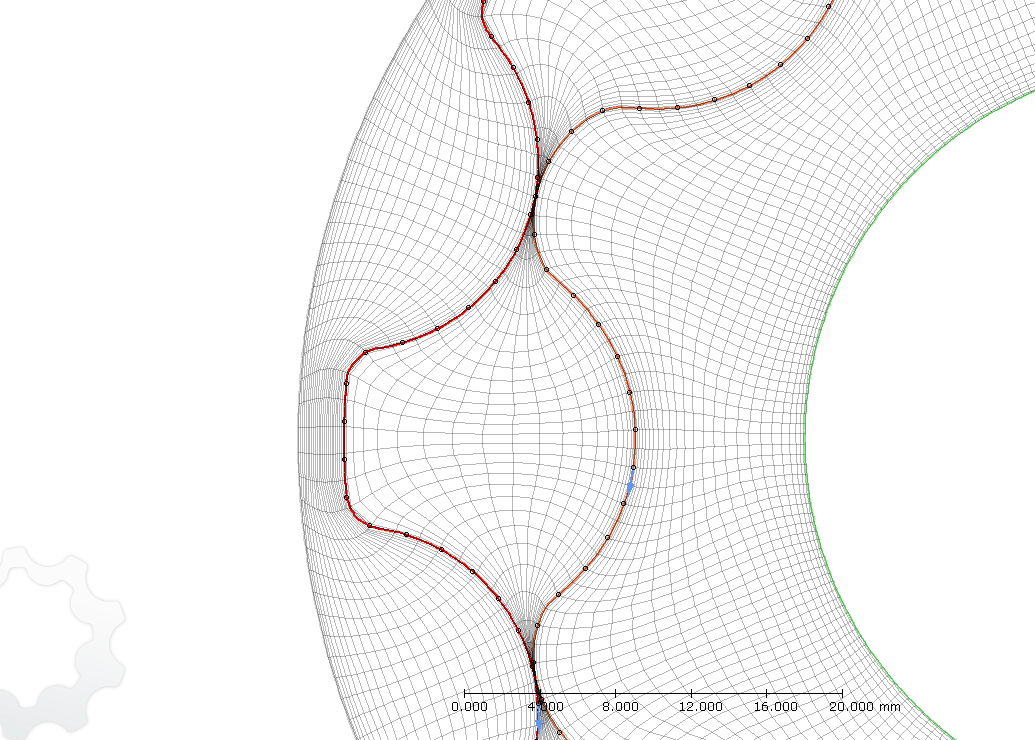

Twisted Hexa (new)

With larger wrap angle values the inner element angle decreases using the standard meshing approach of TwinMesh. To increase the element quality the element orientation can be changed to follow the wrap rotation. On the axial sides prism elements are included to realize the reorientation of the hexahedral elements.

Video

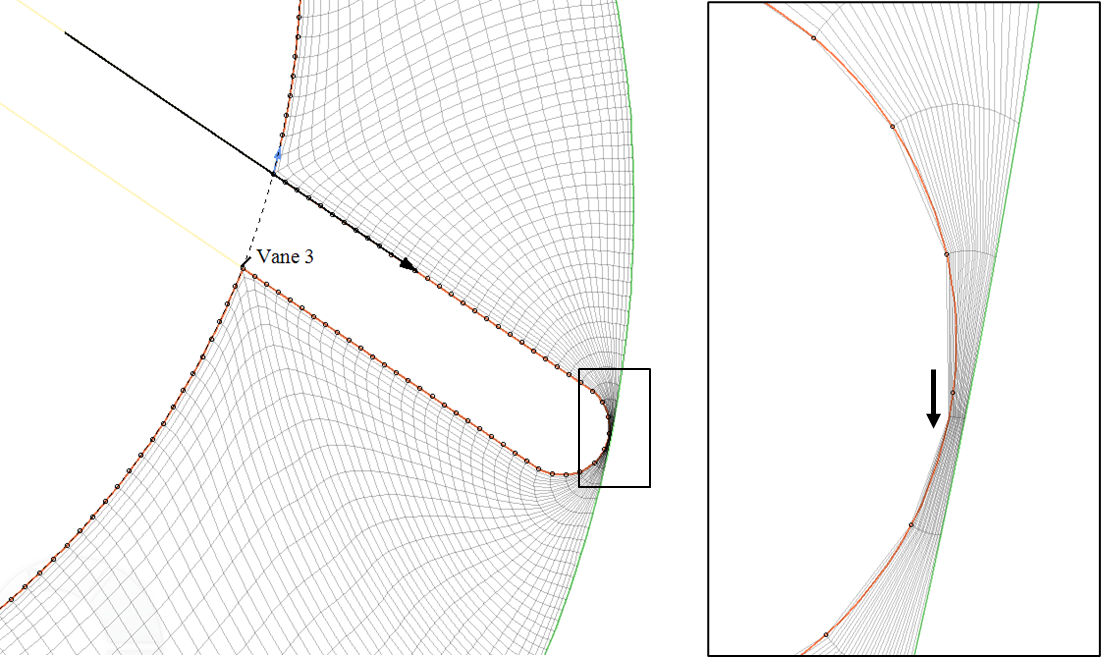

The meshing algorithms of TwinMesh™ 2022 allow nodes moving on the surfaces (opposite to the side they are fixed) from one time step to the next. To keep geometry details like edges geometry points can be created at those locations. The nearest node is then mapped on this geometry point.

Video

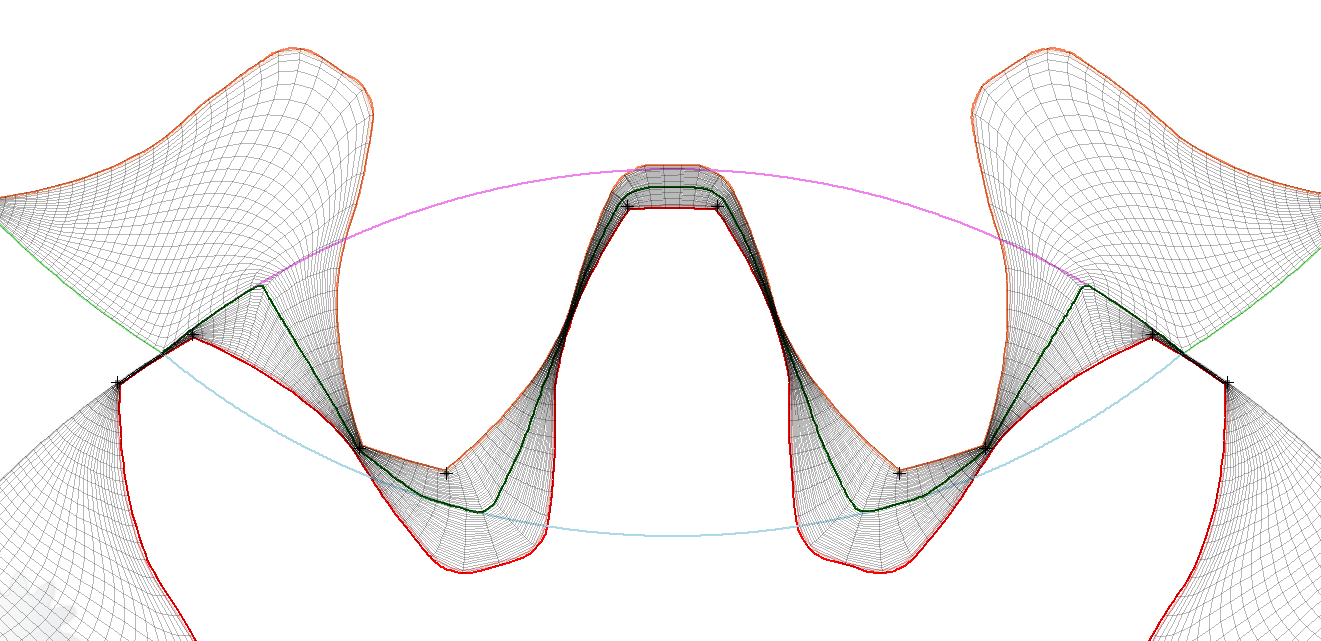

The discretization of the gap depends on the location of the nodes in the gap region. The gap position and sometimes shape depends on the rotor position to the casing. The automatic gap detection in TwinMesh™ 2022 will map a node on the location of the smallest distance between the rotor and the casing or between the rotors of a double rotor machine. This leads to a more continuous gap resolution from one time step to the next.

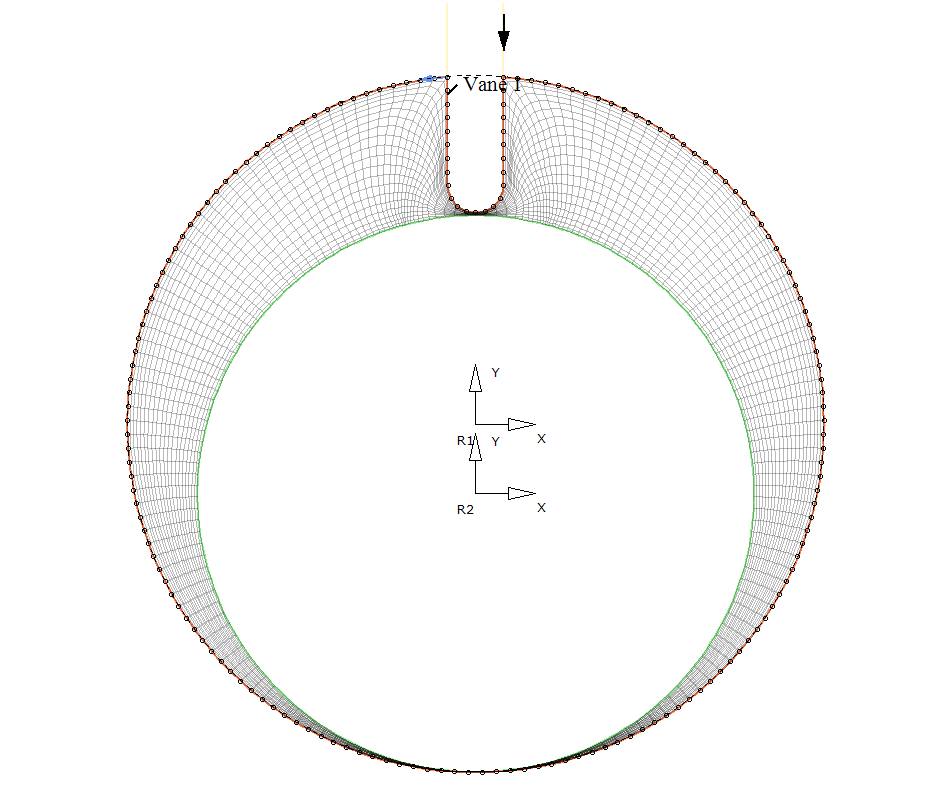

The meshes of the axial gaps are connected by grid interfaces to the main working chamber meshes. For the OuterFix meshing method, the nodes on the rotor surface move from one time step to the next. The motion of the meshes of the axial gaps then has to follow these moving nodes to ensure a 1 to 1 node connection at the grid interface. This new option ensures the same mesh deformation for each rotor position. It prevents overlapping elements or gaps at the interface. This is important especially for the use in Ansys Fluent.

The setup template is now integrated in TwinMesh™ 2022 as a part of the vane pump engine to start the simulation right after export.

Create setup templates for Ansys Fluent cases

The setup of the CFD simulation for Ansys Fluent is now available for nearly all types of machines. The simulation can start right after exporting all the files out of TwinMesh.

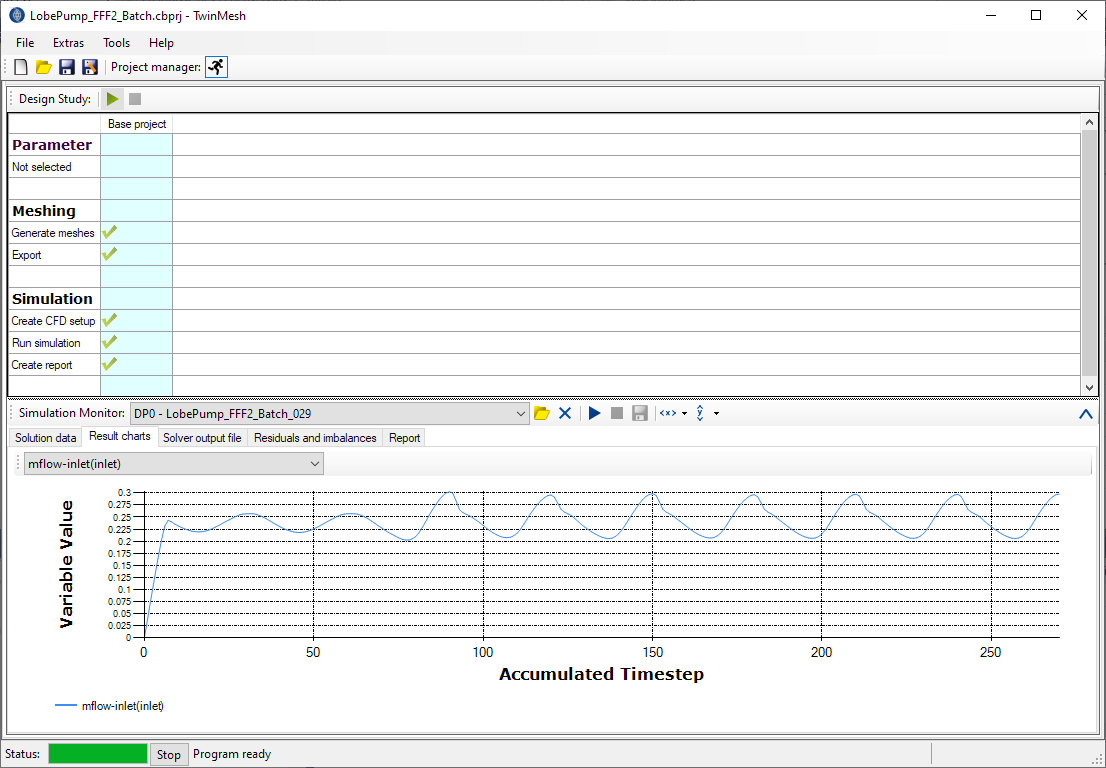

A CFD simulation with ANSYS Fluent can be started and monitored with the TwinMesh project manager on a local windows machine.

Enjoy working with this great new release of the industry leading software for structured grid generation for rotary positive displacement machines! In order to get the new version of TwinMesh™ please contact us or your local TwinMesh™ reseller.