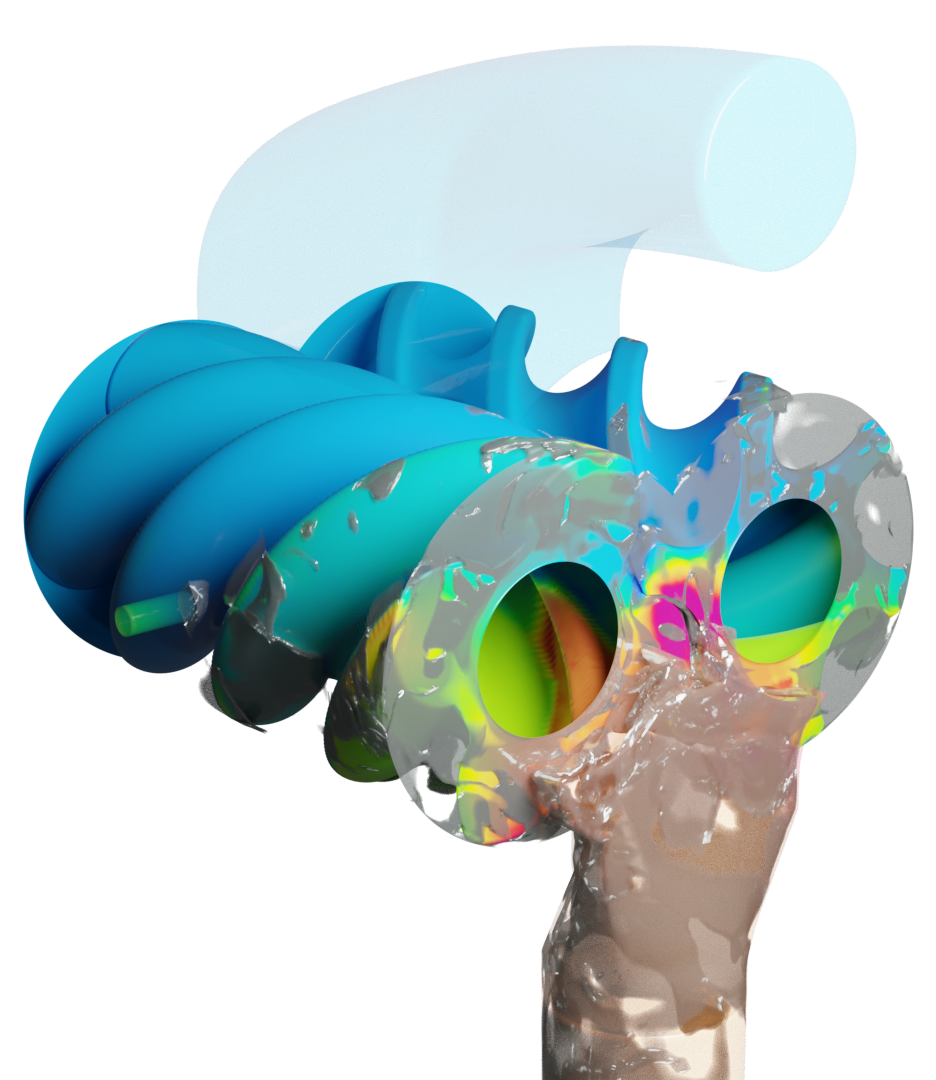

While development and simulation of screw compressors for heavy gases as air or refrigerants are quite usual, those for light gases, here especially hydrogen as future carrier of green energy, make high demands on internal clearance sizes, rotor profiles, and operating conditions to ensure high efficiency. This also poses a challenge for the numerical CFD simulation since reduced clearances, higher pressure ratios, and increased tip speeds require high-quality meshes, better spatial and temporal resolutions, and stable numerical models for high-speed flows. But numerical simulation is a crucial point to boost product development, make performance predictions, and enable digital twins.

The challenges are even higher when water injected or water flooded hydrogen compressors are developed and simulated. Multi-phase models with phase transition and the capability to capture thin films are necessary to examine sealing, cooling, and lubrication of the water. Recently, Jan Gehrmann from Aerzener Maschinenfabrik GmbH discussed these topics in his presentation “Screw Compressors for Green Hydrogen” with a number of industry experts at TNO Netherlands, Workshop hydrogen compression.