TwinMesh Blog

Topics on Reliable CFD Simulation of Rotary PD MachinesThe TwinMesh 2024 Release is here! Find out what’s new!

The new release of TwinMesh 2024 is available and allows the CFD simulation of more complex applications.

Screw compressors for green hydrogen at Aerzen: Demands and challenges

While development and simulation of screw compressors for heavy gases as air or refrigerants are quite usual, those for light gases, here especially hydrogen as future carrier of green energy, make high demands on internal clearance sizes, rotor profiles, and operating conditions to ensure high efficiency.

Great success stories from our rapidly growing TwinMesh customer base

The TwinMesh™ user group grows and grows and grows! We are thrilled to follow and support our customers on their way to improve and optimize their machines reaching the next level in design and performance.

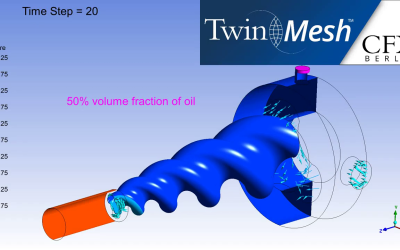

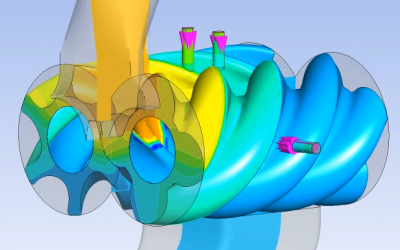

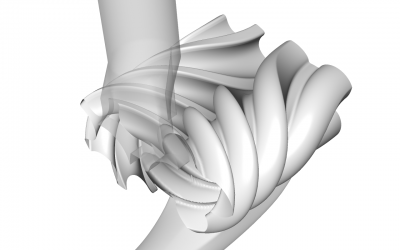

CFD simulation of oil injection into conical rotary compressor with free surface model

This animation shows a conical rotary compressor with non-parallel variable pitch rotors that compresses air from 1 bar to 5 bar.

Preview of new applications with the TwinMesh 2024-Release

The new release of TwinMesh, version 2024 coming in October 2023, allows the CFD simulation of more complex applications.

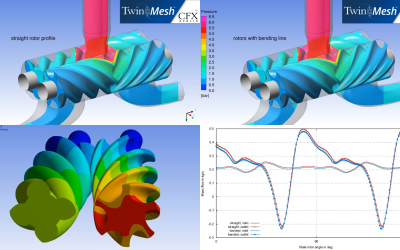

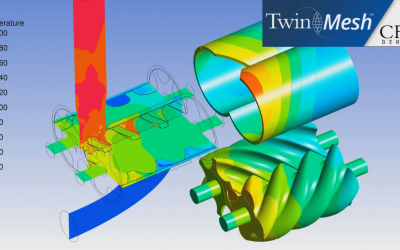

CFD simulation of positive displacement machines considering the bending line due to pressure forces

In this CFD simulation, a double flow / two-sided SRM screw compressor has been setup with air at inlet pressure 1 bar, outlet pressure 6 bar and rotational speed of 12,333 rpm.

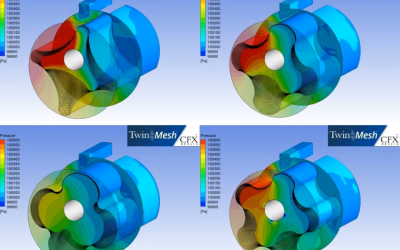

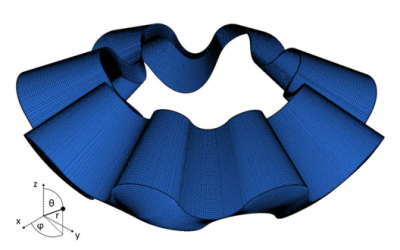

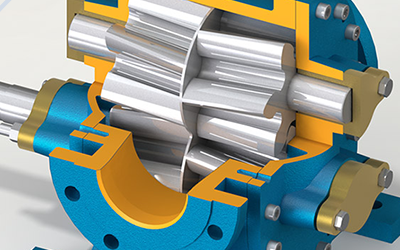

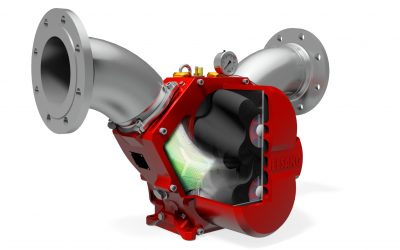

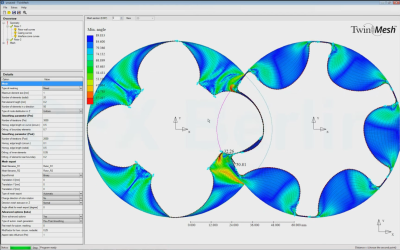

CFD Simulation of Internally Geared Positive Displacement Machines

In an internally geared positive displacement machine, an externally lobed inner rotor rotates inside an internally lobed outer rotor. The outer rotor has one lobe more than the inner one, the rotation axes are displaced.

New paper on numerical investigation of compression and expansion process of a twin screw machine

Increasing the efficiency of twin-screw machines is beneficial for gas compression and expansion applications. A research team from Taiwan used a computation fluid dynamic approach to obtain the flow field and efficiency of a twin-screw machine that used R-134a as the working fluid.

kontruktionspraxis published TwinMesh™ 2023 release notes

kontruktionspraxis published an article about TwinMesh™ 2023. konstruktionspraxis is the leading trade journal for developers and designers in mechanical, apparatus and vehicle engineering, electrical engineering and other metal and plastics processing industries.

TwinMesh™ 2023 released

We are pleased to announce the new release of TwinMesh™ 2023. We added many new features like adding deformation to the rotors and the casing. This gives you an even more realistic flow behaviour inside the machine. Read further for getting information about enhancements and new features in TwinMesh™ 2023.

CFX Berlin at the International Conference on Screw Machines 2022 in Dortmund

We participated in this year’s International Conference on Screw Machines and had a really good time. From September 7th to 8th experts from academic research and industry gathered in Dortmund to present and discuss the latest developments in screw compressor technologies.

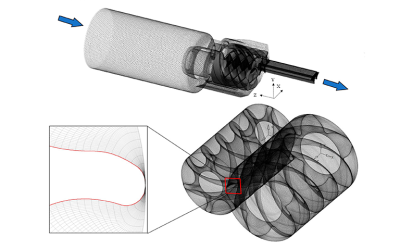

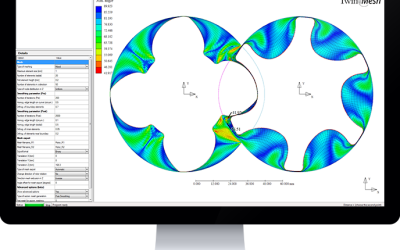

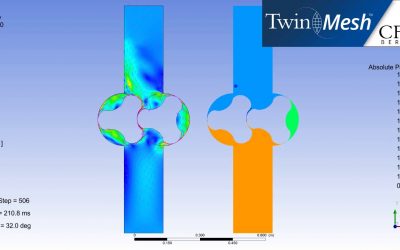

CFD simulation of oil injection in screw compressor

TwinMesh™ 2023 automatically generates high quality structured meshes of the rotating parts of PD machines and eliminates common numerical limits.

In this example you can see pressure distribution as contour plot on the rotor surfaces and on a cut plane on the left hand side; additionally, velocity at inlets and near the outlet is shown by streamlines in purple with a length of 2.5 ms.

TwinMesh™ 2022 released

We are pleased to announce the release of TwinMesh™ 2022. This brand new release of TwinMesh™ includes many new features that further improve the quality of meshes for complex geometries. Read further for getting information about enhancements and new features in TwinMesh™ 2022.

Exciting Applications of TwinMesh in Industry and Science

The success of the revolutionary meshing solution TwinMesh™ continues and grows more and more! TwinMesh customers in industry and science show their exiting papers, success stories and validation projects. A lot of things happened during the last couple of months and it is a great success.

TwinMesh Webinar

Next free TwinMesh webinar, March 30, 2022 at 2pm (CEST): find out more about how TwinMesh and Ansys CFD allow for reliable 3D CFD analysis of rotary positive displacement machines such as screw compressors, lobe pumps, vane pumps, Wankel engines, gear pumps, progressive cavity pumps, or scroll expanders!

TwinMesh™ by CFX Berlin at NAFEMS World Congress 2021

We are pleased to announce that TwinMesh by CFX Berlin will be exhibitor at NAFEMS World Congress 2021 from October 25-29 in Salzburg, Austria. The NAFEMS World Congress covers every aspect of CFD, FEA and multiphysics engineering analysis and simulation.

Webinar Recording | TwinMesh™ & Ansys CFD for Reliable CFD Analysis of Rotating PD Machines

This video by CFX Berlin is a webinar recording from 10th June 2021 and it demonstrates how to perfom reliable CFD analysis of rotating positive displacement machines using TwinMesh™ and Ansys CFD.

Webinar | High efficiency Compressors, Volumetric Pumps and Centrifuges engineering

In this webinar on September 29th 2020 you can learn about the state of the art in terms of engineering simulation tools, together with the best practices and methodologies used by market-leaders for the design and development of: compressors, centrifugal pumps (centrifugal, axial, single / multi impeller, etc.), and volumetric machines (pistons, lobes, gears, etc.).

Great Success Stories from TwinMesh™ Users at CAE Conference

Watch here new and interesting TwinMesh™ success stories of happy users, held at the International TwinMesh™ Users Summit at the CAE Conference in Vicenza, Italy

International TwinMesh™ Users Summit 2019, October 28-29, Vicenza, Italy

The first International TwinMesh™ Users Summit will take place on 28th and 29th October 2019 at the TwinMesh™ exhibition booth of the International CAE Conference in Vicenza, Italy. Come and meet us and other TwinMesh™ users!

CFX Berlin took part in the 9th International Conference on Compressor and Refrigeration (ICCR)

During the whole conference, we answered a lot of questions at our stand together with Zhenya Yang from our TwinMesh channel partner PeraGlobal. In the technical sessions, we gave three presentations on TwinMesh applications

How TwinMesh™ helps to improve innovative pump technology

We are pleased to announce that Kolektor is presenting their latest novelty, the core pump, at the well-known CTI Symposium which takes place from 13-16 May 2019 in Novi, Michigan, USA. On their LinkedIn profile Kolektor states: "Main pump...

International researchers from KITECH in Korea present their latest work using TwinMesh™ at the 29th IAHR Symposium on Hydraulic Machinery and Systems

In their paper “Preliminary Design and Performance Analysis of a Positive Displacement Hydraulic Turbine” Arihant Sonawat supervised by Dr. Jin-Hyuk Kim and their colleagues looked into the causes of pulsations in torque, pressure, and flow rate due to the...

TwinMesh™ 2019 released

We are pleased to anounce the release of TwinMesh™ 2019 – another big and important step in CFD based analysis and design of rotary positive displacement machines. TwinMesh™ 2019 offers developers of rotary PD machines a further improved workflow and many exciting new features. Read further for getting information about enhancements and new features in TwinMesh™ 2019.

Preview of Conjugate Heat Transfer (CHT) for PD Machines Using TwinMesh™ 2019

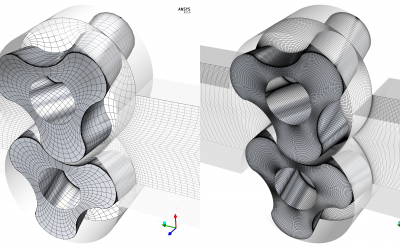

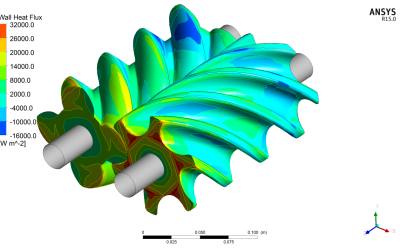

Preview on new features in TwinMesh™ 2019: CFD simulation of a SRM screw compressor with heating of rotor and casing solids with ANSYS CFX. We implemented User Fortran routines in TwinMesh 2019 that connect non-overlapping parts of the fluid-fluid interfaces to the interior solid surfaces to account for temperature and heat flux exchange.

“The Momentum Keeps Up”

Good news is on your way – the success of the revolutionary meshing solution TwinMesh™ continues and grows more and more! Scientific papers, conference presentations, success stories, validation projects, and new reference customers – a lot of things happened during the last couple of months and it is a great success.

Preview of Mesh Interpolation and Non-Reflective Boundary Conditions in TwinMesh™ 2019

The next preview of new features in TwinMesh™ 2019: we implemented a mesh interpolation method in User Fortran. So far, the time step size of the CFD simulation has to be set according to the desired revolution speed and the prescribed angle increment of the pre-generated meshes from TwinMesh. Now it is possible to set an arbitrary time step size, and the corresponding mesh is calculated with a spline interpolation between the pre-generated meshes at run-time.

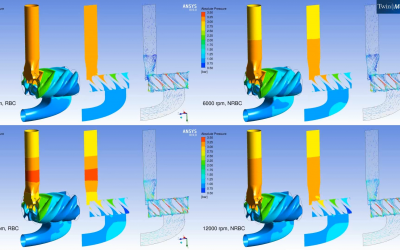

Preview of Non-Reflective Boundary Conditions in TwinMesh™ 2019

Preview on new features in TwinMesh™ 2019: we have implemented non-reflective boundary conditions (NRBC) in ANSYS CFX via User Fortran in a stable and robust way so that they can be used for positive displacement compressors instead of the standard openings which are reflective (RBC). While RBC lead to standing waves, especially at pressure side with mass flow strongly pulsating and even flow reversal, NRBC allow pressure fluctuations from pressure port to travel to the outlet and leave there without any artificial reflections so that mass flow is more uniform and realistic.

TwinMesh 2017 released

New Release TwinMesh 2017 is now available. New features of TwinMesh 2017 include vane pumps and orbital motor as new machine types, variable pitch for screw machines, many function and GUI improvements and a tet grid generator for axial gaps. Click here to find out what is new in TwinMesh 2017!

TwinMesh helps developing waste heat recovery system

With its working principle of a positive displacement machine the scroll expander is a real challenge for 3D CFD. Luckily, BOSCH knows where to look for experts in that field. CFX Berlin provides the right tools, and experience to take such a challenge. Find here a presentation on numerical simulation of a scroll machine using TwinMesh and ANSYS CFX.

TwinMesh and its customer numbers accelerate

2016 has been an exciting year for us. With a steady increase in customer numbers we are very happy to welcome our latest TwinMesh users: Danfoss and Scherzinger Pump Technology. Moreover, we would like to share what Eaton has to say about TwinMesh and CFX.

Merry Christmas and a Happy New Year 2017

Merry Christmas and Happy New Year from TwinMesh & CFX Berlin Software GmbH

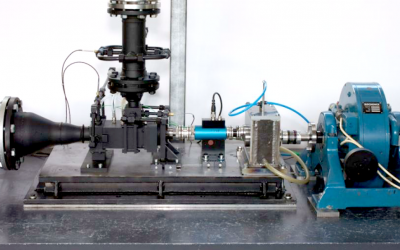

CFD Simulation and Result Validation for a Twin Screw Expander Including Leakage Flows

It Works! Read this Blog about CFD Simulation and Result Validation for a Twin Screw Expander Including Leakage Flows. Measurements come from TU Dortmund, CFD Simulation was done by CFX Berlin.

TwinMesh 2016 – released

We are happy to inform you that our new release TwinMesh 2016 is now available. Find out what is new in TwinMesh 2016.

CFX Berlin at 2016 Purdue Conferences : CFD Analysis of a Dry Scroll Vacuum Pump Including Leakage Flows

During the 2016 Purdue Conference on July 11-14 we had the opportunity to present two of our recent works on CFD of positive displacement machines. One popular topic was the industrial application of scroll machines. Find and read the full paper here!

New Rotary Lobe Pump Design Standard Set with CFX Berlin’s TwinMesh

Hugo Vogelsang Maschinenbau GmbH, one of Germanys top leading rotary lobe pump manufacturers, uses TwinMesh for their CFD analysis to improve performance, durability, and life time for their rotary lobe pumps.

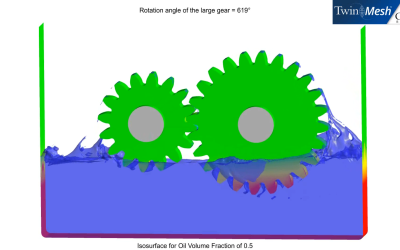

Gear Box Lubrication CFD Analysis

One of our Master degree students evaluates whether the combination of TwinMesh grids and ANSYS CFX simulation are helpful for gear box lubrication analysis. Although there are only first results available yet I found this video quite amazing and therefore decided to share it here in this Blog.

Spotlight on the Impact of Mesh Resolution

In order to produce reliable computational fluid dynamics (CFD) results, the mesh resolution can have a severe impact on both, qualitative and quantitative simulation results.

In this short article we present data from three different cases where correct mesh resolution is inevitable. Read through the text, have a look at the data, and be stunned by the fact that a coarse mesh resolution and quality can give you poor and in the worst case unreliable results.

Advanced Postprocessing of Screw Compressor CFD Results

Video example for advanced postprocessing of screw compressor cfd results using script-based tracking of massless particles in ANSYS CFD-Post.

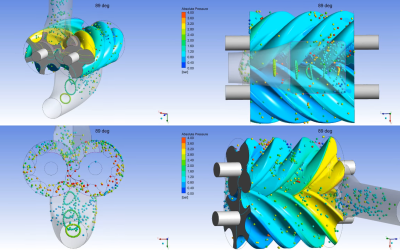

First international Masters’ Thesis with TwinMesh completed at Feng Chia University, Taiwan

We are proud that the first international Masters’ Thesis using TwinMesh has been completed.

CFD Simulation of a Screw Compressor Including Leakage Flows and Rotor Heating

CFD simulation of a screw compressor incl. rotor heating – this article shows setup steps and results for the simulation of a dry screw compressor

TwinMesh Workflow Video

Find out how easy mesh generation with TwinMesh works – we have recorded a video for you!

Latest TwinMesh Introduction Webinar Slides

Find out more about the TwinMesh software for structured grid generation and our simulation approach and download our latest TwinMesh Introduction Webinar Slides.