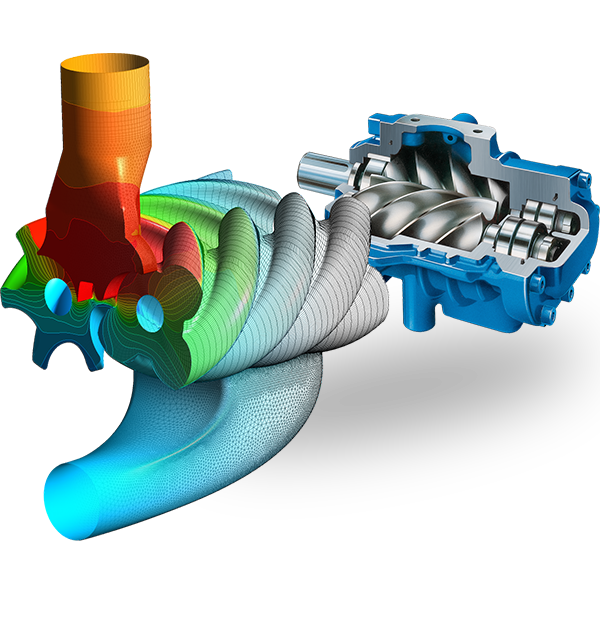

TwinMesh for Reliable CFD Analysis of Screw Compressors and Expanders

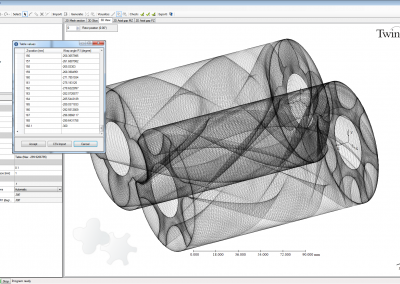

Combining TwinMesh and leading CFD solvers offers engineers a unique, efficient and fast workflow for transient, three-dimensional computational fluid and thermal analysis (CFD) of Screw Compressors, Expanders and Superchargers.

Developers of Screw Machines Need to:

- Analyse the impact of changing operation requirements (e.g pressure difference, rotation speed, impact of external temperatures, etc.)

- Have a deep understanding of their machine dynamics

- Be able to answer specific customer demands (CoP, noise emission)

- Produce fast and reliable answers

Thanks to our software TwinMesh real virtual product development is available for twin screw machines! TwinMesh and leading CFD solvers together allow for efficient and reliable CFD analysis of screw compressors and expanders.

No More Numerical Limits

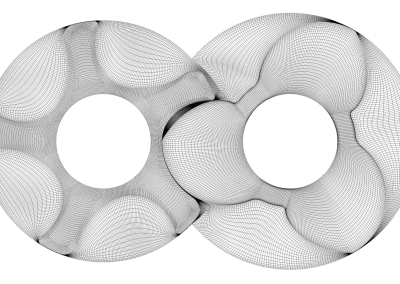

Common limitations of CFD software packages for screw compressor or expander geometries such as limited physics, insufficient mesh resolution or numerical errors due to bad mesh quality or interpolation errors or overlapping mesh method are redundant for the TwinMesh approach.

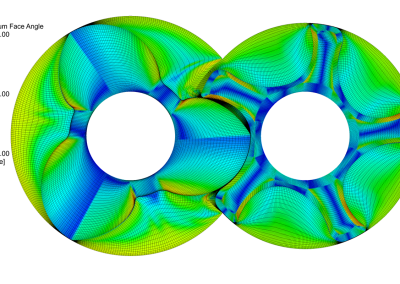

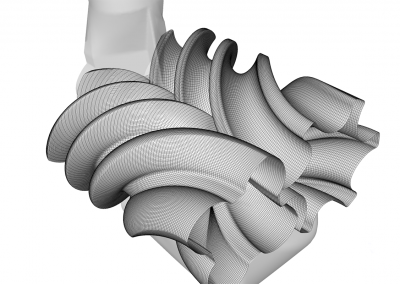

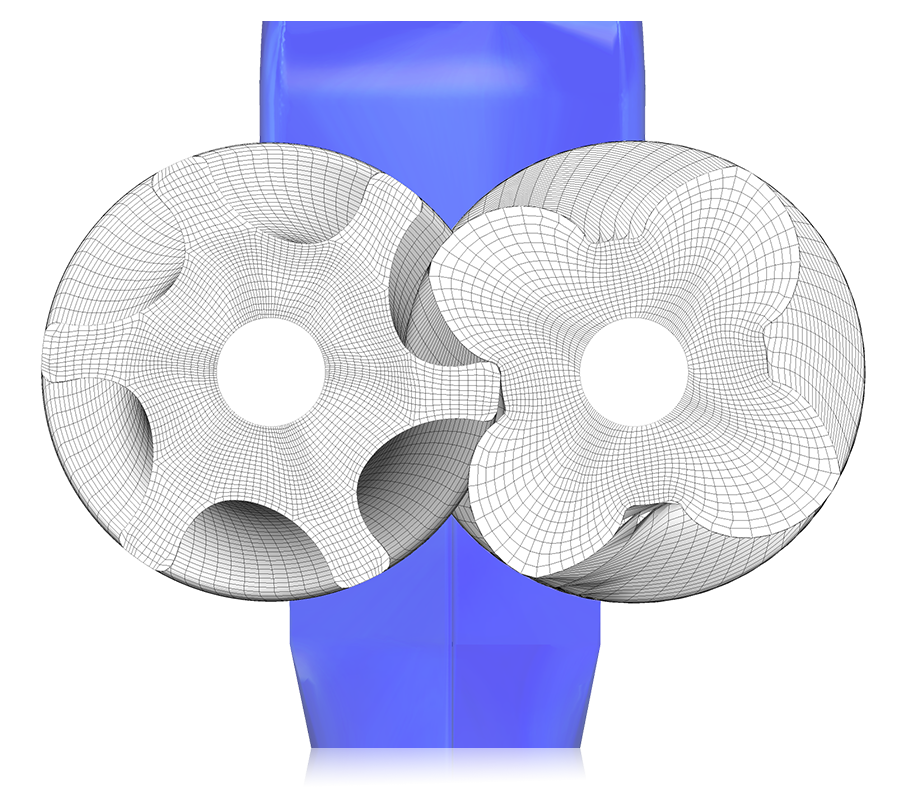

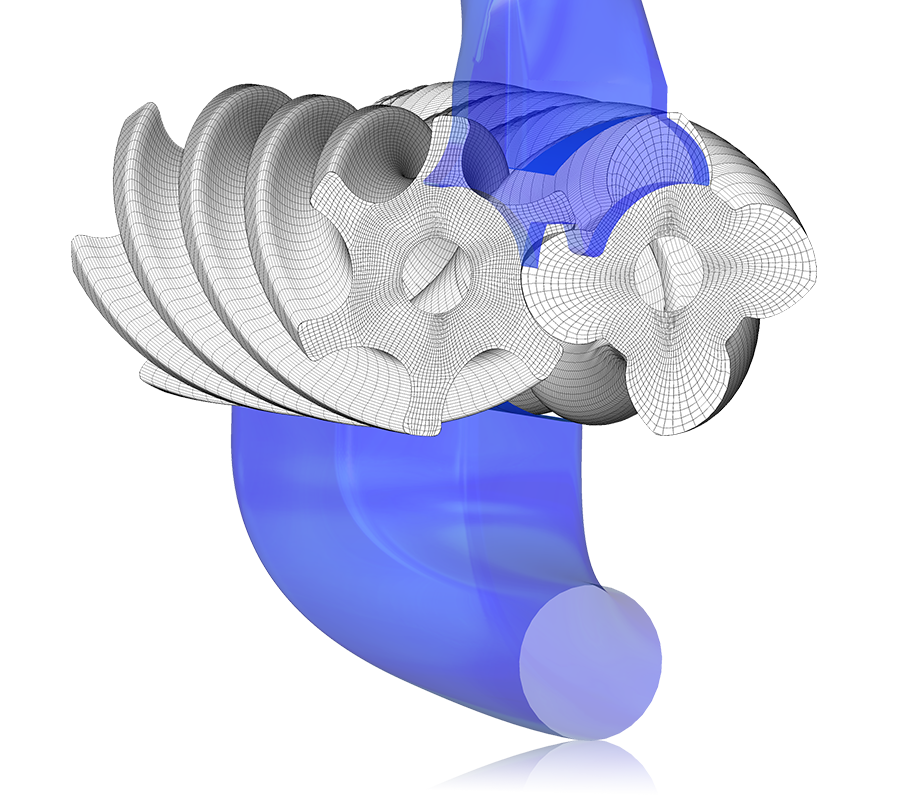

Using structured grids from the TwinMesh software engineers of screw machines get access to the full capability of CFD modelling available in modern CFD packages. The high quality meshes from TwinMesh result in reliable and stable CFD simulations at moderate model sizes and moderate calculation times for transient analysis. Even for multiphase simulation such as oil-injected or water-cooled screw compressors and expanders.

Reliable CFD Analysis of Screw Compressors and Expanders

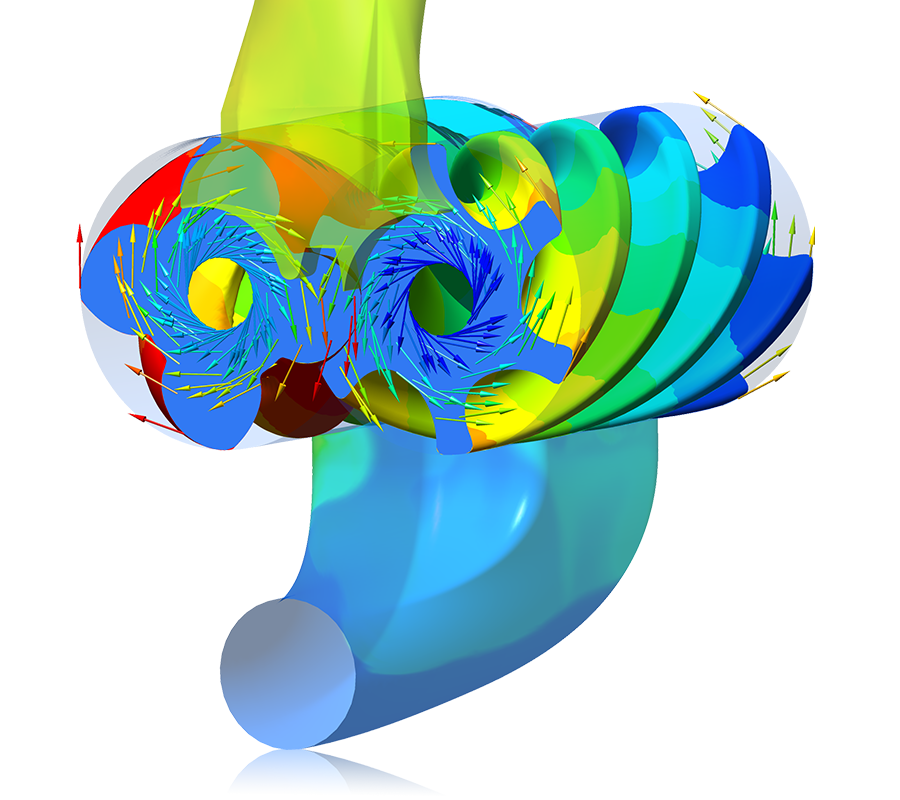

And what can designers expect? CFD analysis results generated with TwinMesh and CFD software provide design engineers of oil-free (single-phase) and oil-injected (multi-phase) screw compressors and screw expanders with essential information such as:

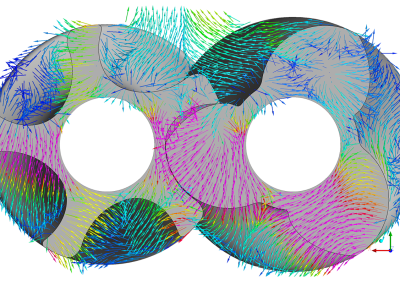

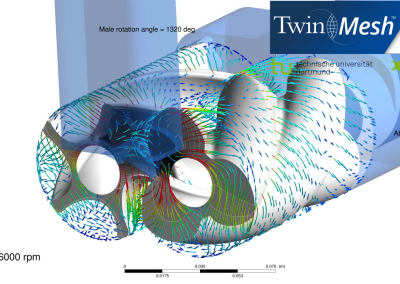

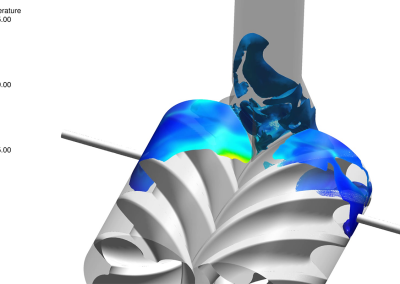

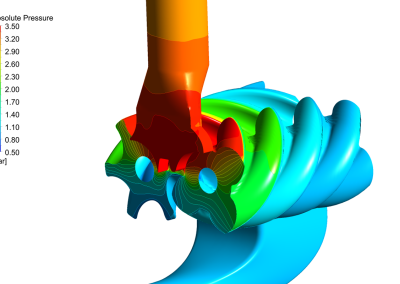

- Velocity, pressure, and temperature fields within the working chambers, in axial and radial clearances, and in suction and discharge ports

- mass flow rates at different operation points

- Torques, moments, forces and machine efficiency (CoP)

- Leakage and losses

- Pulsation behaviour of the machine

- Mechanical wear, lubrication and cooling

- Duration and magnitude of acoustic sources (emission)

TwinMesh and CFD software packages together make a reliable, modern, and state-of-the-art engineering tool, which allows for fast, reliable and efficient analysis and optimization of oil-free and oil-injected screw machines.

Better Designs

Increase machine performance, efficiency, and durability by a better understanding of complex phenomena inside your machine.

Speed & Flexibility

Reduce your time-to-market and fasten your response time to changing demands significantly by massive use of virtual prototyping.

Drive Innovation

Drive real innovation by getting deeper insight into the details of your products and their interaction with connected systems.

Reduced Costs

Reduce development and manufacturing costs by massive use of virtual product development instead of time consuming measurements on physical prototypes.

CFD Results of Screw Compressor and Screw Expander Simulations

Animations of Screw Compressor Simulations

Flow in working chambers of a screw expander

Oil-injected screw compressor (multiphase)

Related blog entries

The TwinMesh 2024 Release is here! Find out what’s new!

The new release of TwinMesh 2024 is available and allows the CFD simulation of more complex applications.

Screw compressors for green hydrogen at Aerzen: Demands and challenges

While development and simulation of screw compressors for heavy gases as air or refrigerants are quite usual, those for light gases, here especially hydrogen as future carrier of green energy, make high demands on internal clearance sizes, rotor profiles, and operating conditions to ensure high efficiency.

Great success stories from our rapidly growing TwinMesh customer base

The TwinMesh™ user group grows and grows and grows! We are thrilled to follow and support our customers on their way to improve and optimize their machines reaching the next level in design and performance.

TwinMesh is available for these PD Machines